Semiautomatic and automatic mandrel tube bending machines

Together with the leading factories for tube deformation equipment in Europe we develop and supply various tube bending machines for precision and productive 3D tube bending and fabrication process. We are able to offer standard or special solutions from semi-automatic version of machine till full-automatic, CNC controlled, servo-driven high-production equipment with the possibility of auxiliary special units, like tube punching after the bending and external automatization with loading-unloading, transferring devices or robotic equipment.

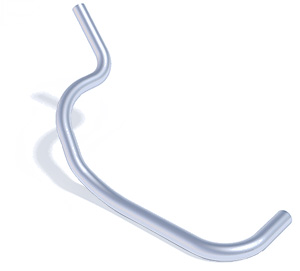

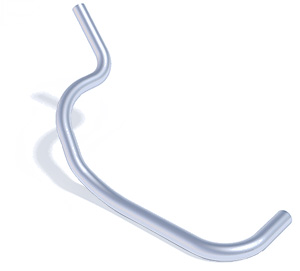

Tube bending machine can deal from standard to hard tasks and application with tight and small radius of bending, thick wall or thin wall tube materials, complicated bends geometry, several radiuses in one tube to bend with different tool stacks etc.

Key features

From 1 axis semi-automatic machine (only bending movement) till complete automatic productive solutions

Machine offers from 6 till 120 mm diameter of tubes

NC or CNC controlled

Complete solutions together with automation equipment if necessary

Tube bending tools for your task and applications

One or several bending stacks

Ergonomy and compact construction of main machine

World known brands for all main components

Hydraulic or servo-drived for auxiliary axes

|

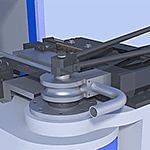

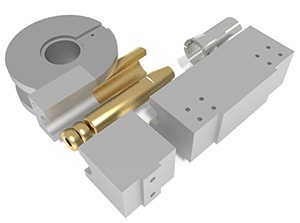

Ergonomic tool positioning area together with the compact bending main head unit for easy installation of tools, effective clamping on the machine and save of more space to prevent the collision of tube during the bending to machine parts and tooling.

|

|

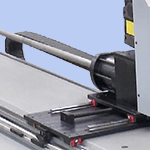

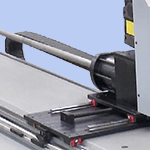

Carriage with magnetic stops if manual movement of carriage execution or full control of the stroke to feed the tube from PLC panel or CNC control. Hydraulic clamping of tube inside collet. For special solutions carriage could be equipped with booster unit.

|

|

Tube bending machine is equipped by Schneider / Telemecanique touch screen control (for semi-automatic machine) or full power CNC control for 3- and more axis machines. Control is used to input bending sequence with the value of each axis. CNC control allows to make the cycle in full-automatic mode with the possibility of preliminary simulation of movements to check collisions.

|

|

Additional units and devices such as loading-unloading devices, possibility to punch the tube after the bending, welding seam detection, springback measuring device etc. could be ordered and installed for full-controlled tube bending process.

|

Tube bending process

Cold tube bending process today is the important technology and fabrication process for lot of applications from furniture and tubes for heating, conditioning, water equipment to the large tubes in shipbuilding, offshore industry, gas and oil transfer, chemical industry etc. Tube lines are commonly used in automotive and aerospace industry, agriculture machinery, different liquid transfer equipment etc. Draw bending process with the help of bending die to form the necessary radius of bend with the rotation of the clamp tube is the most general technology to obtain strict and precision radius till the extremely tight adjustments like 1D or smaller. Effective tube bending machine is the key for production process and moreover the way for repeatability with all parts which is impossible to obtain with the manual bending. Use of servo-drived axes for secondary movements like work of clamps is necessary and allows to get the most precise setup of the machine with maximum precision for manufactured parts or possibility to work with very delicated tasks, for example bending of small elongation thin walled tubes.

|

|

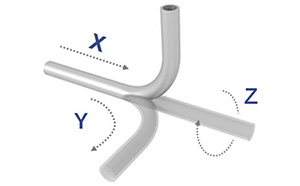

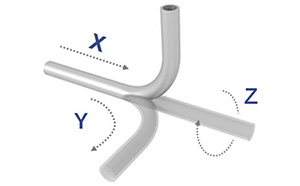

Moveable axis

All standard machines are used X, Y, Z coordinates for main movements. Other auxiliary movements are the clamp movements which are standard hydraulic or servoelectric.

X - movement of carriage, feed the tube toward working area (optionally automatic)

Y - move of bending arm to perform the bend (always automatic)

Z - rotation of the tube (optionally automatic)

We can supply the solutions from 1 to 9 controlled machine axis. XYZ axis with automatic control always means the automatic CNC tube bending machine.

|

|

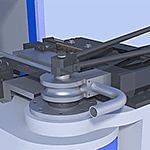

Mandrel bending

All our machines are mandrel bending machines. This means the use of special tool - mandrel with the feeding to put inside the tube and extraction after to make more controlled the deformation of material during the bend process to bend with minimum ovalization of the tube and appearance of wrinkles and corrugations on the surface. Mandrel is one of most important elements in tube bending technology and highly important in thin wall tube bending or complicated radius.

|

|

Technical details

|

|

PT-35

|

|

PT-42

|

|

PT-60

|

|

PT-80

|

|

PT-120

|

|

Max. diameter of tube, mm

|

|

35x2

|

|

42x2

|

|

60x3

|

|

80x3,5

|

|

114x8

|

|

Max. bending radius

|

|

125

|

|

125

|

|

220

|

|

260

|

|

340

|

|

Max. length of tube, mm

|

|

3000

|

|

3000

|

|

3000

|

|

3000

|

|

4000

|

|

Accuracy of X-axis (feed), mm

|

|

0,05

|

|

0,05

|

|

0,05

|

|

0,05

|

|

0,05

|

|

Accuracy of Y-axis (bend), deg

|

|

0,1

|

|

0,1

|

|

0,1

|

|

0,1

|

|

0,1

|

|

Accuracy of Z-axis (rotation), deg

|

|

0,1

|

|

0,1

|

|

0,1

|

|

0,1

|

|

0,1

|

Technical details are for standard machines and could be modified under the customer request and application to proceed.

Send the request

Please send us your contact information and we will reply as soon as possible.

All "*" fileds are required to fill in

Attention: All the brands, machines, manufacturers and trademarks are used only for the information, are not connected with PRECITOOLS and are property of their respected owners.

|

|