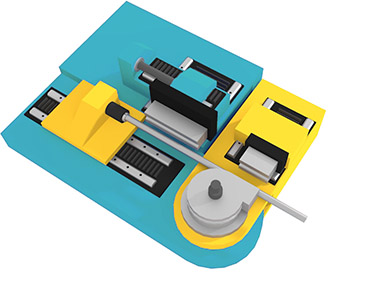

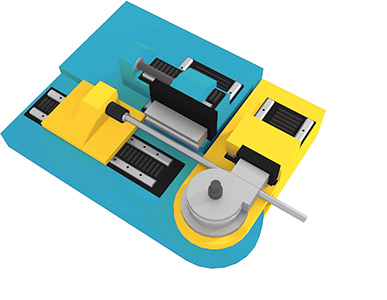

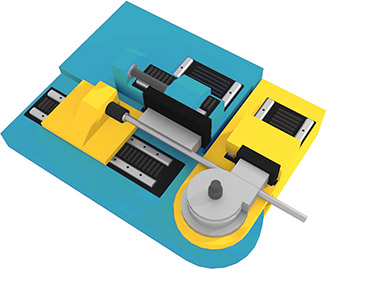

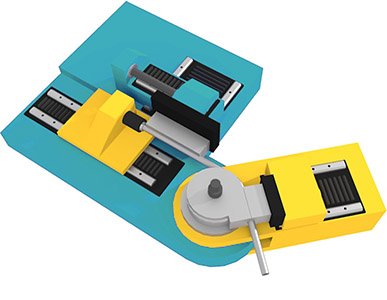

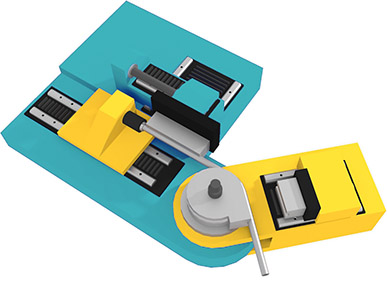

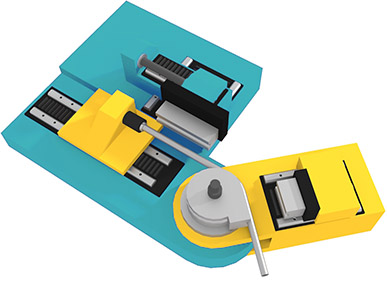

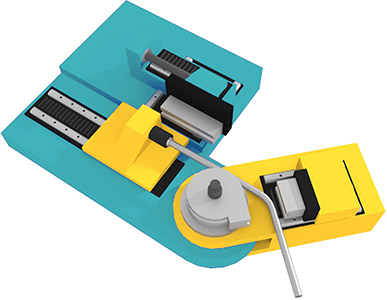

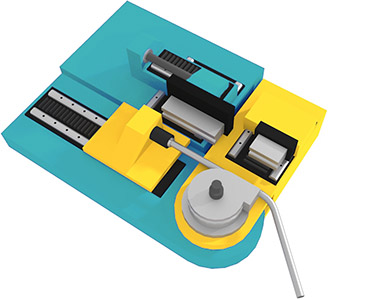

Draw tube bending processDraw tube bending means the bending of the tube around of the bending die with the use of bending arm of tube bending machine. Tube bending tools are made according to the tube sizes and radius of the required bends. All the movements usually are the same for every manufacturer of standard tube bending machine with the possibility of mandrel bending (mandreless bending machine construction has some differences). All the movements could be controlled with different ways (from manual or hydraulic to servo-drived) but the specification of movements is equal.To show the simple bending of tube we prepared the draw bending visualisation which could be easy to understand for more knowledge of the tube bending process. Please note that because it is one bend the rotation of tube to bend in 3D mode as well as mandrel loading-unloading movement is not presented. For sure if you need better explanation you can contact us.

Attention: All the brands, machines, manufacturers and trademarks are used only for the information, are not connected with PRECITOOLS and are property of their respected owners. |