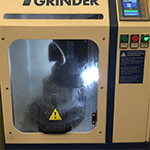

Grinding machine for punching tools F-GRINDER (Punch and die grinder)We would like to present you the semi-automatic grinding machine F-Grinder to sharp and maintenance of punching tools (punches and dies) for various models and systems of punching presses: Trumpf Trumatic, Trumpf Trupunch, Boschert, Haco, Pullmax , Amada, Finn-Power, Prima-Power, Durma, Schiavi, LVD, Strippit, Danobat, Yawei, Nisshinbo, Euromac, Baykal, FIM, Murata Muratec, Rainer, MVD, Tailift, SimasV, Yangli, Peliant, SNK, Pullmax, Hesse-Maschinen, Ermaksan, Dener, ITEK, SMD etc.Universal machine F-Grinder is suitable for all main tool systems, very easy machine for operation and is the key for proper care of your punching tools for maximal duration of tool life. On the market there are various versions of grinding machines for punch and dies. Our solution is one of the best choice for the price-possibilities which could be budgetary comparable with desktop machines with much more advantages such as base frame and setup control panel.

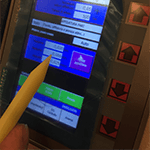

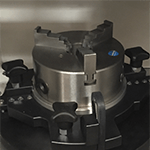

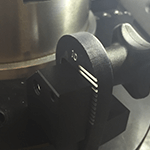

Key featuresA - F Stations for Thick Turret toolsGr0 - Gr3 for Trumpf tools Grinding of all possible sizes of Multitools (Revotool, XMTE, MTE, MT, Multimatrix etc.) Angle grinding for forms whisper and double whisper One universal chuck for all sizes - no additional adapters required Closed working area to protect operator Manual mode only to touch the surface, after the grinding is automatic Control panel SIEMENS Touch with your local language

Why grinding of punching tools is important?For sure every punching tool has mechanical wear and every hit of the punching machine reduces the tool life. There are a lot of different production factors to reduce the tool life in addition, like quality of the metal, thick sheets for punching, use of force and hole sizes near the possible limit of the machine, thin shapes and much more. Moreover weared tool is the reason of the additional burr on the part after the punch and increasing of necessary force -> effects the full machine working life. In this case every operator and user should verify and resharp in time the punch tool to save the good balance in quality and the maximum life of the tool. Delayed resharpening causes the necessity to remove more material and in this case reduces the possible quanity of resharpening cycles for one tool.Technical details

MediaSend the requestPlease send us your contact information and we will reply as soon as possible.All "*" fileds are required to fill in Attention: All the brands, machines, manufacturers and trademarks are used only for the information, are not connected with PRECITOOLS and are property of their respected owners. |