|

|

|

CNC hydraulic press brakes

Together with the leading factories for sheetmetal deformation equipment in Europe we prepare and supply CNC press brakes for effective and productive bending of sheetmetal inside workshop. Press brake is one of the important machines in sheetmetal fabrication to perform the necessary deformation for end-product shape. All our hydraulic CNC press brakes are fast precision equipment with the use of standard Promecam - Euro bending tools, following of European safety standards and regulation with the availability of multi-axis servodrived backgauge even for very complicated applications in fully automatic bending cycle CNC-conrolled.

Key features

From 60 to 275 tons of bending force

From 2100 to 4000 mm of bending length

modern CNC control

Precision and fast backgauge from 2 to 5 moveable axis

CNC crowning as standard

Tool system: Promecam - EURO style, WILA as option

Solid and robust construction of main machine

World known brands for all main components

High safety standards

|

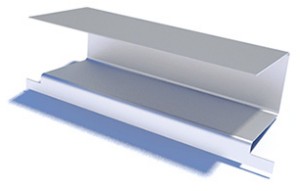

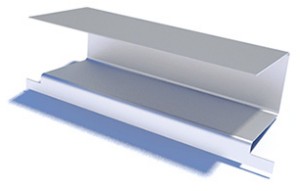

CNC controlled crowning system in standard supply with the system of wedges to compensate the deflection of the frame for performing of precision bends, even outside of the machine centers or with thick materials.

|

|

High quality fast and effective servodriven backgauge with 2 axis controlled by CNC in standard supply. Backgauge could be upgraded up to 5 controlled axis to perform most complicated and special bends or use of various tools and heights.

|

|

Every press brake equiped with 2 arms of frontal support with the possibility of manual movement. Supports allow to bend long sheets for operator or to load even heavy pieces. Automatic supports with the possibility of following of bend could be supplied as additional option.

|

|

Every press brake is supplied with laser system AKAS to use the safety beam for protection of hands and provide the high quality safety and security for operator during the work process. Our press brakes meet highest safety regulation according to the requirements in EU, Customs Union etc.

|

Press brake sheetmetal bending

Sheetmetal bending with the use of upper beam of press brake with the travel of top bending tool (punch) towards to the fixed bottom tool (die) is the most popular and general technology of bending today.

Construction of press brake has 2 side C-frames connected with the table (post for the bending die) and moveable beam with the top tool to proceed with the bend. Backgauge on the rear part of bending tool controls the positioning of the part. There are many variable parameters and the options such as separate cylinders for each part of the beam, connected robot to make automatic bending, front tables to follow the bend, special back gauges etc.

|

|

Cybelec CNC

Press brakes are equipped with the system CYBELEC ModEva 15T with the standard features:

2D graphic display 12"

Windows based

Bending sequence, tooling, piece positioning, collisions etc.

Ethernet and USB connections

Multi-language

Under the request 3D CNC Delem is optionally available.

|

|

|

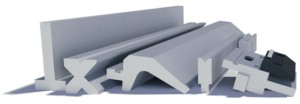

The possibility to offer the machine with all necessary tools allows us to proceed the "turn-key solution" together with the delivery and installation of the machine at your factory. The use of high quality components, effective contruction and precision guides ensures the long use of the machine with the constant quality in bending.

We also quite flexible to proceed standard as well as special projects dedicated with high tonnage or length bending or use of special auxilary components and equipment.

Optionally the machine could be equipped with any tooling solutions: WILA tool system, quick change mechanical top clamps, pneumatic or hydraulic quck change for top and bottom tools etc.

|

Technical details

|

|

PS 2100.60

|

|

PS 2600.90

|

|

PS 3100.120

|

|

PS 3100.200

|

|

PS 4100.200

|

|

Max. bending force, tons

|

|

60

|

|

90

|

|

120

|

|

200

|

|

200

|

|

Max. bending length, mm

|

|

2100

|

|

2600

|

|

3100

|

|

3100

|

|

4100

|

|

Distance between columns, mm

|

|

1600

|

|

2050

|

|

2550

|

|

2550

|

|

3550

|

|

Daylight opening, mm

|

|

475

|

|

540

|

|

540

|

|

530

|

|

530

|

|

Motor power, kW

|

|

5,5

|

|

7,5

|

|

11

|

|

18,5

|

|

18,5

|

|

Beam stroke, mm

|

|

210

|

|

260

|

|

260

|

|

260

|

|

260

|

|

Throat gap, mm

|

|

410

|

|

410

|

|

410

|

|

410

|

|

410

|

|

Table width, mm

|

|

60

|

|

60

|

|

60

|

|

90

|

|

90

|

Technical details are for standard machines and could be modified under the customer request and application to proceed.

Send the request

Please send us your contact information and we will reply as soon as possible.

All "*" fileds are required to fill in

Additional

Attention: All the brands, machines, manufacturers and trademarks are used only for the information, are not connected with PRECITOOLS and are property of their respected owners.

|

|

|

|