We offer for our customers all bending tooling solutions for hydraulic and electric press brakes of main clamping systems in the world - Promecam or European style, Trumpf - WILA, LVD-W, Beyeler-Bystronic tools: punches and dies, hemming sets, stamps, punchholders, die holders, adapters, die inserts, radius tooling with standard lengths and sectional types with rich selection of standard types and possility to make any special tools under request of customer including the length of 6000-8000 mm in one piece.

We are able to assist the customer to recommend tooling according to his parts as well as to prepare the sequence or quotation for special shapes if necessary.

Possibility to store lots of standard positions of bending tools with the marking and cutting before shipment allows to provide good delivery time even for big orders. All our bending tools are produced in Italy with the use of CNC machinery and quality control during different stages of production. For bending tools only high quality steels C45 or 42CrMo4 are used. The precision grinding allows the best contact with the material. All our tooling pass the temperature treatment till 55/60 HRC for long life use and effective protection against damages.

Together with the tooling we can supply the .DXF model for quick import to the CNC-library of press brake.

Bending tools, tooling for press brakes

Not only bending tools

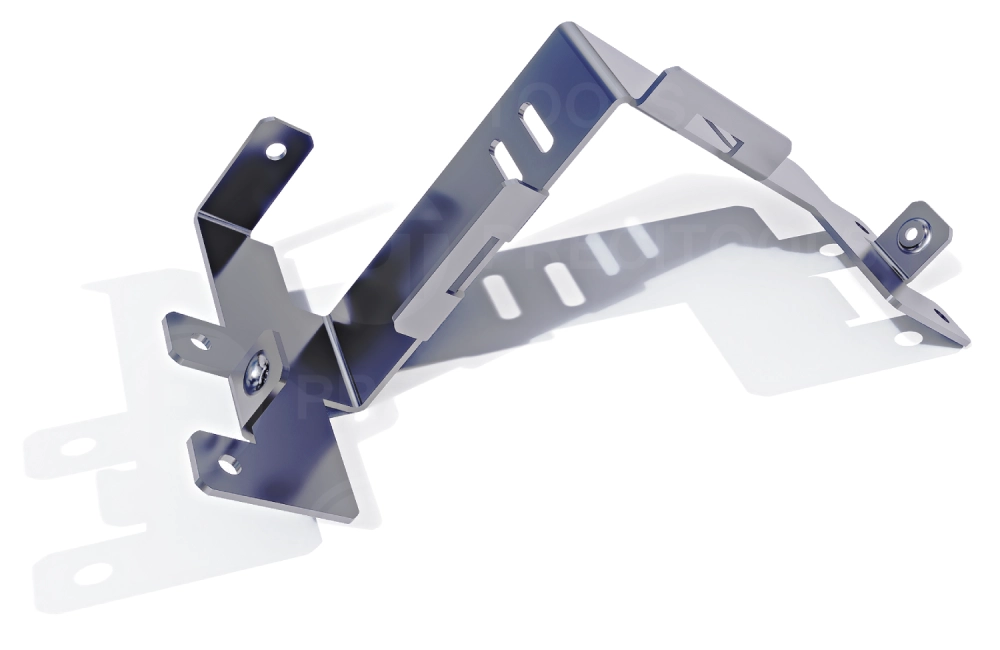

Thanks for wide cooperation with various manufacturers we are able not only to offer standard bending tooling positions for your press brake but complex solutions to make the parts which request normally stamping presses or punching presses. These could be actual for typical parts for stamping, busbars bending and forming, fabrication of electrical connector parts, brackets etc.

- Forming tools for press brake

- Holes punching tooling

- Louvers forming

- Emboss, countersink and other forming punching operations

- Cutting

- Small flanges bending

- Bending near holes with minimal deformation

- Small radius bending

- Inserting

- Forming and stamping multiple parts in one stroke

Bending process visualization

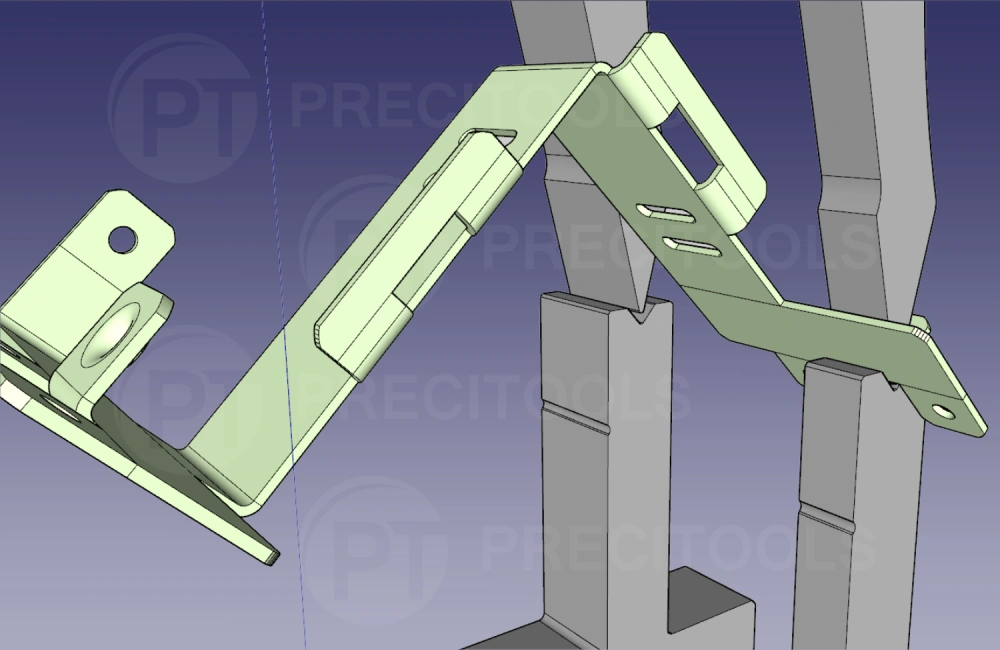

We use CAD-based bending visualization to precisely plan and validate the press brake bending process before production starts. By digitally defining the bending sequence, we can evaluate multiple setup options and eliminate the trial-and-error typical of manual planning. This results in smoother production launches, shorter lead times, and greater confidence that the part can be bent exactly as intended.

Our software allow us to determine the most efficient bending order, select the optimal punches and dies, and check full machine compatibility. During simulation, we run detailed collision and clearance checks involving the part geometry, tooling and, if necessary press brake holders and components. This helps identify potential issues early—such interferences and collisions.

For standard or symmetrical components, we typically prepare complete 2D simple drawings, but for complex geometries or non-symmetrical shapes we are able to createthe entire project in a 3D environment.

Our software allow us to determine the most efficient bending order, select the optimal punches and dies, and check full machine compatibility. During simulation, we run detailed collision and clearance checks involving the part geometry, tooling and, if necessary press brake holders and components. This helps identify potential issues early—such interferences and collisions.

For standard or symmetrical components, we typically prepare complete 2D simple drawings, but for complex geometries or non-symmetrical shapes we are able to createthe entire project in a 3D environment.