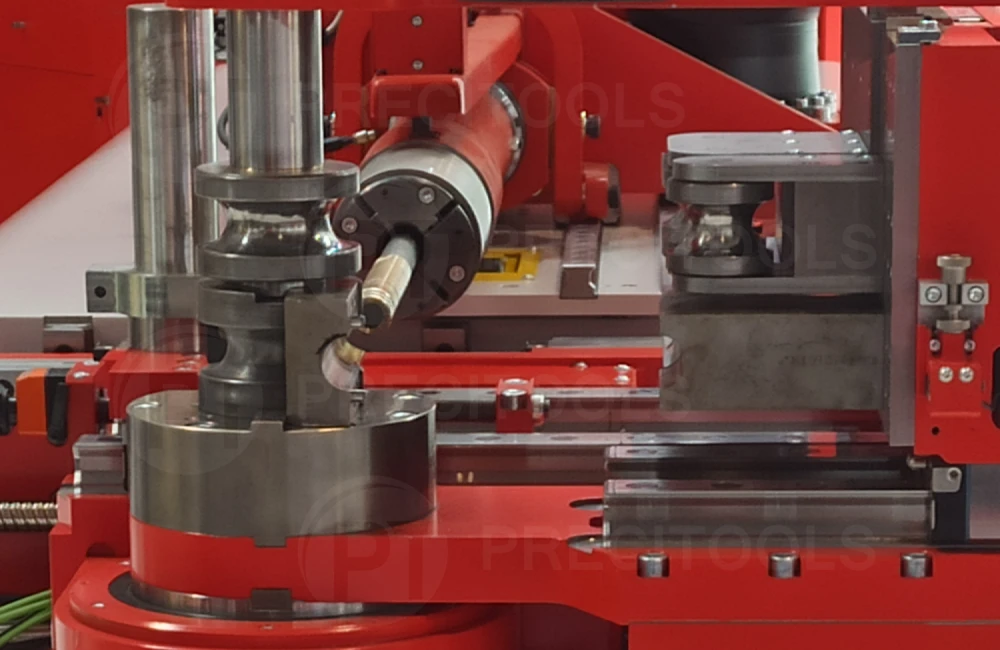

Our specialization is the tooling and tools for draw tube bending process with the forming of tube radius according to the size of bending die with the use of mandrel tube and pipe bending machinery.

We offer:

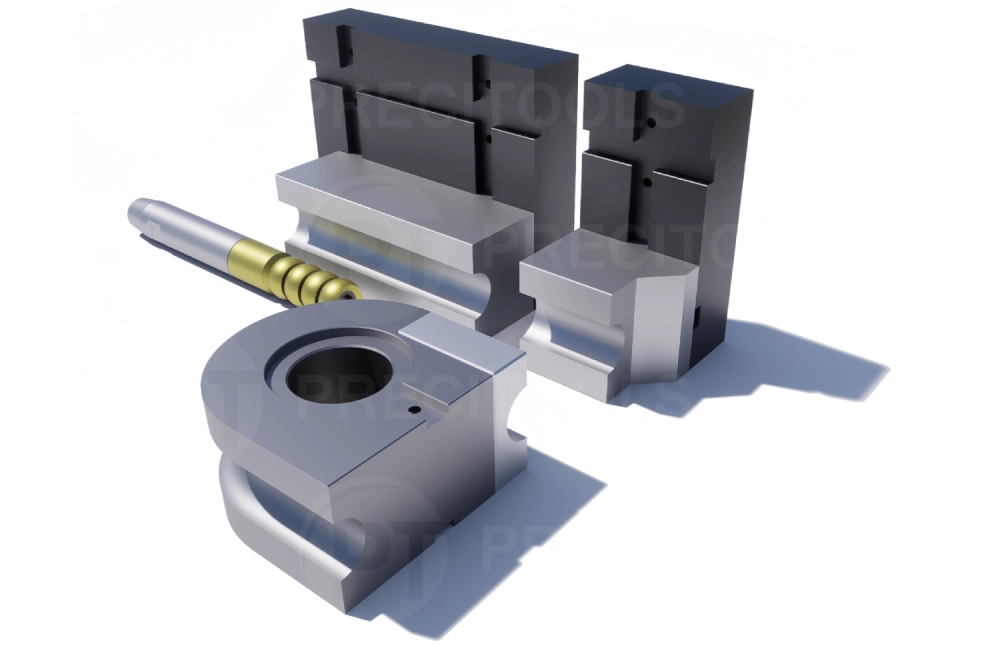

- Separate parts or complete sets of tube bending tooling according to the drawings

- Ball-flexible mandrels in steel or aluminum-bronze alloy

- Single-stack (single level) or multi-stack (several levels) of tooling

- Development of tooling sets for left and right bending; 2 headed tube bending machines

- Profile milled tools for bending after tube end-forming or presenting of additional elements like nuts, rings, couplings etc.

- Round tubes; oval tubes; rectangular or square tubes or special profiles

- Short clamps with minimal straight part on tube

- Push-bending tooling with rolls for variable radiuses

- Additional holders and fixators including quick-change elements and eye-bolts for handling

- Use of drawing from our database or your drawings

- Tooling hardening for the long use

- Any difficulty of project